Failing Panel Wall Replaced with Redi-Rock MSE Wall to Save Shopping Center

Redi-Rock solution saves investors millions

THE CHALLENGE

When the initial cost estimate to remove and replace a failing panel wall at the Lakeview Shopping Center in Brewster, New York, came back over the value of the development itself, the outlook for a sale of the property didn't look good. And, when the city of Brewster threatened to condemn the entire 177,000-square-foot (16,450 square meter) facility if a repair didn't take place, it was time for a creative solution.

Cosmo Marfione, P.E, an engineering consultant for investors Urstadt Biddle Properties Inc., reached out to an old associate, Danny Romanello of Lea-Rome Excavating. Marfione had worked as an intern for Romanello in 2001, and he was going back to his old boss to see if he had any sage advice on creating a more cost-effective solution.

"He shows me this plan of this new retaining wall, and I say 'Holy smokes.' And he says, 'How can we do this cheaper?'" shared Romanello of their initial exchange.

It was a Sunday afternoon, and the two tossed around ideas of how to lower the $14 million price tag of the current plan, which included steel sheet piles to withhold the earth and uphold the parking lot of the shopping complex while the old wall was completely removed and replaced.

It was Romanello who suggested looking into whether a Redi-Rock precast modular block wall could be built in front of the existing wall instead of removing the wall. He had worked with local Redi-Rock supplier Mid Hudson Concrete Products on previous projects, and he thought it might be possible.

THE SOLUTION

Upon further investigation, building a Redi-Rock wall in front of the failing panel wall was not only deemed a feasible solution, but the cost came back at half the original estimate to remove and rebuild a wall where the failing wall stood.

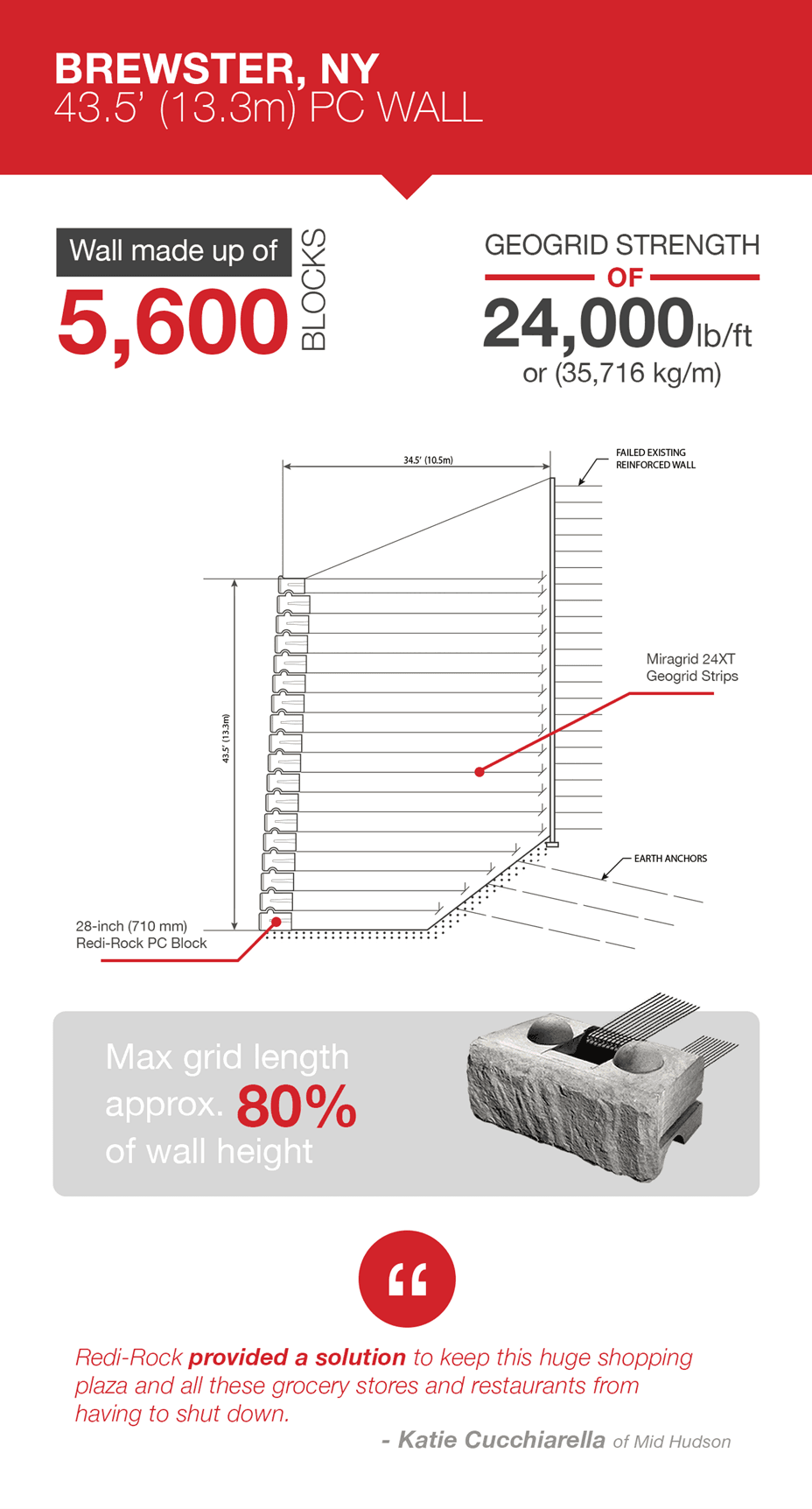

While the solution was feasible, it wasn't a small undertaking. At its tallest point, the new wall would stand 43.5 feet (13.3 meters) tall, and it would stretch almost 1,200 feet (366 meters).

"This was our largest retaining wall that we've done as far as block count total, as well as height," said Katie Cucchiarella, sales manager for Mid Hudson Concrete Products. "We weren't making Positive Connection blocks at the time, so that was a new product for us as well."

Mid Hudson had been producing other elements of the Redi-Rock system since 2000, but producing the 5,600 Positive Connection (PC) blocks would come with the typical learning curve of manufacturing a new product. PC blocks have a core slot cast through the block where a 12-inch (300-millimeter) wide strip of factory cut and certified geogrid can be wrapped through the block, virtually eliminating any chance of a connection failure for the reinforced modular block wall.

Despite the challenge, Cucchiarella knew "if we strategically work together and Danny gave me enough time to stockpile some material that we would be able to do it."

In addition to the sheer size of this wall and the new product for Mid Hudson Concrete Products, the wall also was designed and constructed within an extremely tight footprint. The property line was just 40 feet from the existing wall, and 200 feet from Bog Brook Reservoir, which provides drinking water for New York City.

THE DESIGN

The project engineers at H2M Architects & Engineers worked closely with Redi-Rock International staff in formulating the new plan for the wall. Having never designed a Redi-Rock wall before, they relied on the Redi-Rock technical support team to craft the best solution within the space constraints.

"Daniel in the engineering department was a huge help with the engineers that did the plans on this project," said Cucchiarella.

"My role was more on project support with the design engineer, so I assisted in project review, specifically the analysis of the critical cross sections of the wall," said Daniel Cerminaro, P.E., engineering consultant with Redi-Rock International.

Cerminaro used Redi-Rock Wall+ Software (RRWall+) to perform the analysis on all modes of failure for the critical cross sections. The mechanically stabilized earth (MSE) wall was designed assuming all pressures from soil and surcharges within the retaining zone of influence, disregarding any contribution from the existing failing wall.

The main challenge was to design an MSE wall within the limited footprint of the space between the existing wall and the property line. With just 40 feet (12 meters) of sloping grade down to the reservoir's property line to work with, the critical wall section would occupy all of this space to satisfy minimum design requirements.

In addition to the space challenge, slope stability analysis showed potential failures. Contributing factors included the existing failing wall and additional weight of the new MSE wall on the existing slope. To address this issue, a system of soil nails was designed to stabilize the slope and drive the potential failure surface deeper into the slope. These slope stabilizers consisted of grouted soil nails that varied in lengths between 30 to 40 feet (9 to 12 meters). The design and construction of the soil nails addressed issues specific to slope stability surrounding the existing and new wall systems, but it was independent and separate from the Redi-Rock retaining wall design.

The critical section of the wall has a height of 43.5 feet (13.3 meters) with grid layers spaced vertically every 18 inches (457 millimeters). Grid lengths are approximately 80 percent of the height of the wall, but shorter grid lengths were used at the bottom of the wall where further excavation would have undermined the existing failing wall. The geogrid consists of Mirafi Miragrid 24XT, which is factory cut and certified to 12-inch (300 millimeter) strips to easily wrap through the center core slot in the PC blocks. This polyester grid is uniaxial with an ultimate tensile strength of approximately 24,000 pounds per foot (35,716 kilograms per meter).

THE INSTALLATION

With entire panels falling off of the existing wall and the backfill material seeping through the facade in numerous locations, the first task in the repair was to ensure the safety of the installation crew. Wire mesh was used to shore up the old wall so that any falling debris wouldn't fall on the crew.

Romanello knew that his crew didn't have any wiggle room on the property line. If they crossed over that line, they'd be infringing on the New York City watershed, and they'd be shut down immediately. So, he split his team into two crews -- one that worked at the top of the wall and one that worked at the bottom of the wall.

"The challenge was trying to do everything from the top because there wasn't enough room to really make an access road," said Romanello. "You could get a piece of equipment down there, but you couldn't get anything back and forth all day...We had 15,000 cubic yards [11,500 cubic meters] of dirt that had to be excavated for the footing for this job 50 feet [15 meters] below you, and there was no way to get down there with a truck."

A self described "machine guru," Romanello knew that the equipment he had wouldn't be able to construct this wall from atop the existing structure, so he rented an excavator with an extra-long reach to accomplish the task.

Lea-Rome Excavating released the project to Mid Hudson Concrete Products at the end of June, and they started shipping blocks in July.

"At the time they started installing [in August] we had stockpiled around 600 blocks on the site, which allowed us to keep up with manufacturing and delivering with their installation," said Cucchiarella.

"The machine that we rented was much more productive than we thought," said Romanello. "It was able to pick up three 1,500 pound blocks at a time and set them down -- not on the wall. There was a small machine on the bottom for that."

Mid Hudson Concrete Products delivered two to three truckloads of the 1,520 pound (690 kilogram) PC blocks, six days a week from July 2018 until January 2019 to keep the Lea-Rome Excavating crews moving on installing the 5,600 blocks that made up the wall.

Lea-Rome Excavating put the finishing touches on the project in May of 2019, ten months after starting the project.

THE OUTCOME

"I don't know what else you could have done to build that wall with anything else," said Romanello of using Redi-Rock PC blocks. "The engineers say that it isn't going to move, and I agree with them after actually building it and watching the way it's built."

In the end, Mid Hudson Concrete Products was able to supply the job on schedule, helping to right a bad situation with the failing wall. They not only helped save the Lakeview Shopping Center with a Redi-Rock solution, but they saved the investors $7 million, in addition to keeping all of the businesses located within the facility thriving.

"Redi-Rock provided a solution to keep this huge shopping plaza and all these grocery stores and restaurants from having to shut down," said Cucchiarella.

PROJECT DETAILS

Project: Lakeview Shopping Center - #216 Owner: Urstadt Biddle Properties Inc. Contractor: Lea-Rome Excavating Project Engineer: H2M Architects & Engineers Manufacturer: Mid Hudson Concrete Products Location: Brewster, New York Year: 2019

PRODUCTS FEATURED IN THIS CASE STUDY

Reinforced Retaining Wall Blocks - Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks.

Limestone Texture Blocks - Redi-Rock Limestone blocks mimic the texture of natural split Limestone.