Retaining Wall System Takes Gold at Olympic Games

Challenging weather, difficult sites, and a tight timeframe were no match for Redi-Rock walls

THE CHALLENGE

In September 2011, PyeongChang, South Korea, secured the right to host the 23rd Winter Olympic Games slated for 2018, finally succeeding after two previous bids fell short. Construction began in March 2014 on the facility that would host of the high-profile Olympic bobsleigh, luge, and skeleton competitions. The sprawling $114.5 million complex was proposed for the rugged mountain pass of Daegwallyeong, nestled between the Alpensia and Yongpyong ski resorts.

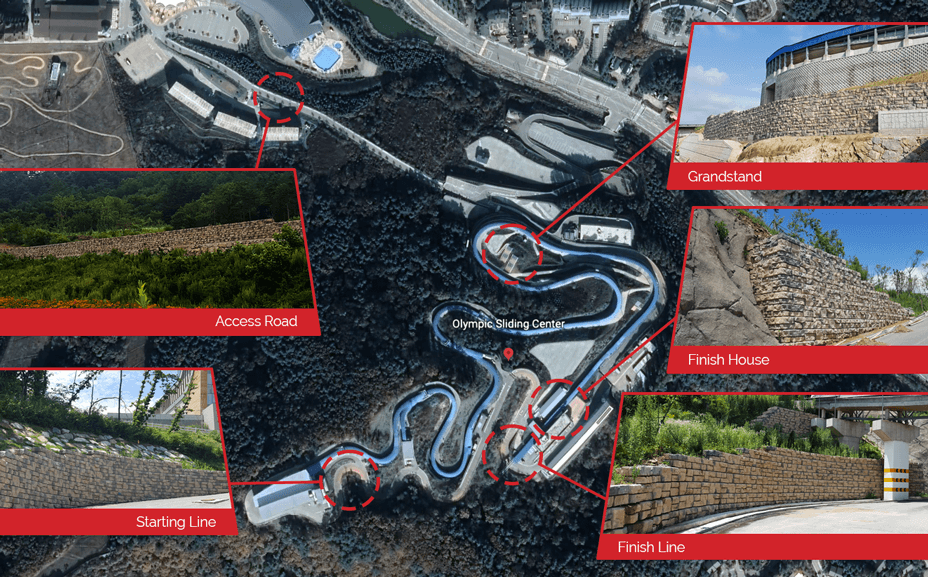

The complex was to include seven buildings, a 6,620-ft (2018-m) sliding surface, and occupy 44 acres (178000 sq m). The site ranged in altitude from 3,084 ft (940 m) above sea level to 2,625 ft (800 m) above sea level. The rough, uneven terrain – coupled with the need to provide ingress and egress for thousands of competitors, officials, and spectators – demanded the installation of several retaining walls across the site.

Five Redi-Rock gravity walls were installed in conjunction with the construction of the Olympic Sliding Centre.

Five Redi-Rock gravity walls were installed in conjunction with the construction of the Olympic Sliding Centre.

THE SOLUTION

The general contractor for the project DL E&C determined that four retaining walls were needed at the site – along access roads near the starting line, finish line, and finish house, and adjacent to the sliding surface to support the spectator grandstand. A fifth location – an access road joining the Centre to the nearby OCEAN700 resort – included two walls and was added to the project later.

DL E&C, in collaboration with the PyeongChang Organizing Committee for the 2018 Olympic & Paralympic Winter Games, evaluated several retaining wall solutions. Considered options included precast concrete panel mechanically stabilized earth (MSE) walls, cast-in-place (CIP) reinforced concrete walls, and Redi-Rock’s precast modular block (PMB) walls.

South Korean manufacturer and installer SEKOROCK Co. was selected to fabricate and install Redi-Rock PMB walls for the five locations. Redi-Rock was the choice for several reasons, including:

One Product, Many Applications The Redi-Rock wall solution offers a variety of block sizes and types, giving engineers great flexibility to solve unique site challenges. For this project, the Redi-Rock product line could meet the engineering demands of each of the five walls, providing uniformity across the venue.

Durability in Difficult Conditions Redi-Rock PMBs are made with wetcast, air-entrained concrete in a controlled environment. Compared to drycast blocks, wetcast blocks stand up better to harsh freeze-thaw conditions and roadway applications where salt may be utilized.

Natural, Native Appearance Redi-Rock blocks offer a rich, textured appearance and can be colored to suit the site’s needs. Textures are modeled after natural stacked stone that blends with surrounding structures and landscapes, giving the finished product a beautiful, native look. Ledgestone texture was selected for the Olympic Sliding Centre.

Custom-colored, Ledgestone texture blocks ensured a look consistent with the regional landscape. This wall secured the roadway between the Olympic Sliding Centre and the adjacent OCEAN700 resort.

Custom-colored, Ledgestone texture blocks ensured a look consistent with the regional landscape. This wall secured the roadway between the Olympic Sliding Centre and the adjacent OCEAN700 resort.

Expedited Installation Redi-Rock offers a shortened installation window compared to other retaining wall products. Weighing between 1,160 – 4,840 lbs (530 – 190 kg) each, these blocks can still be installed with a small excavator and a crew of three. The blocks’ weights and interlocking knob-and-groove technology creates strong interface shear connection and consistent wall setbacks, allowing the blocks to be dry stacked. And with front face areas ranging to 1,656 sq in (1,068,384 sq mm), fewer courses are necessary to reach required wall sizes.

Working in Tight Quarters Redi-Rock retaining wall systems can often be installed in a reduced footprint. The blocks’ gravity system can allow installation without geogrid reinforcement which requires additional excavation. Redi-Rock gravity walls can be designed up to 20 ft (6 m) in height depending on site conditions. The smaller installation footprint helped the crews succeed despite the competing construction demands of the site.

Construction of the Centre and its surrounding infrastructure began in 2014 and steadily progressed until late 2017, when heavy rains and snows coupled with one of the region’s coldest winters on record caused significant icing on the unpaved mountain paths. The unreliable roadways prevented use of typical 25-metric ton construction trucks to move materials to the site. Redi-Rock blocks, however, could be transported on smaller 7-metric ton cargo crane trucks better suited to handle the rut-filled, frozen roadways. The transportation flexibility afforded by the Redi-Rock blocks kept the project on-schedule despite what initially appeared to be insurmountable weather conditions.

Much of the retaining wall installation took place while additional construction was occurring immediately adjacent, sometimes as close as a few feet. Of particular note was the construction of tiered gravity retaining walls in the finish line area. These walls provided the abutments for the raised section of track’s end stretch and also anchored soil around the piers of the bridge.

With less intrusive machinery and smaller crews, Redi-Rock gravity walls can be installed where cast-in-place alternatives cannot.

With less intrusive machinery and smaller crews, Redi-Rock gravity walls can be installed where cast-in-place alternatives cannot.

The bottom wall measured 98 ft (30 m) long by 12 ft (3.65 m) tall and covered 1,292 sq ft (120 sq m). The base of this wall rested roughly 3 ft (0.90 m) from one of the previously placed bridge supports, demonstrating how Redi-Rock gravity blocks can be installed in extremely tight spaces. The second wall formed the bridge abutment and measured 65 ft (20 m) long by 12 ft (3.65 m) tall, totalling 860 sq ft (80 sq m). This wall was installed even closer to an existing support than the lower wall.

THE OUTCOME

Upon its timely completion in December 2017, project participants estimated the use of Redi-Rock reduced the time required for the retaining wall portion of the Centre’s construction five fold and allowed them to meet the challenge of installing a high-quality solution in a very demanding environment. All told, 8,180 sq ft (760 sq m) of Redi-Rock large block retaining wall was installed at the Olympic Sliding Centre and the nearby access roads with the project utilizing 1,450 41 in (1030 mm) blocks in Ledgestone texture.

Redi-Rock’s innovative block design allows for the creation of smooth curves without compromising stability or demanding highly technical installation adjustments.

Redi-Rock’s innovative block design allows for the creation of smooth curves without compromising stability or demanding highly technical installation adjustments.

The Olympic Sliding Centre – now reverted to its original Alpensia Sliding Centre moniker – has also managed to avoid the derelict fate of many previous purpose built Olympic venues. It remains in use today as one of only two operating sliding facilities on the continent. The Centre offers training, competition, and programs for athletes from across Asia and beyond to develop their skills and support the establishment of national federations in their countries. The PyeongChang 2018 Legacy Foundation is also working closely with the International Bobsleigh and Skeleton Federation (IBSF) to host further international competitions in the 2022-23 winter season and beyond.

PROJECT DETAILS

Project: PyeongChang Olympic Sliding Centre Owner: Gangwon-do Olympic Committee Manufacturer: SEKOROCK Co. General Contractor: DL E&C Location: PyeongChang, Gangwon-do, South Korea Year Built: 2017

PRODUCTS FEATURED IN THIS CASE STUDY

Gravity Retaining Wall Blocks - Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the eart

Ledgestone Texture Blocks - Redi-Rock Ledgestone blocks give projects a random, stacked stone look.