City Chooses Redi-Rock To Create Space for Bridge Construction

Gravity retaining walls allow city to avoid disturbance of existing roadbed while protecting pedestrians and cyclists

THE CHALLENGE

The Razorback Greenway in Northwest Arkansas had its skeptics when the project was unveiled. People wondered if the bike path would only appeal to extreme cyclists. However, the trail system has become a resounding success across demographics, with a major economic impact in the region.

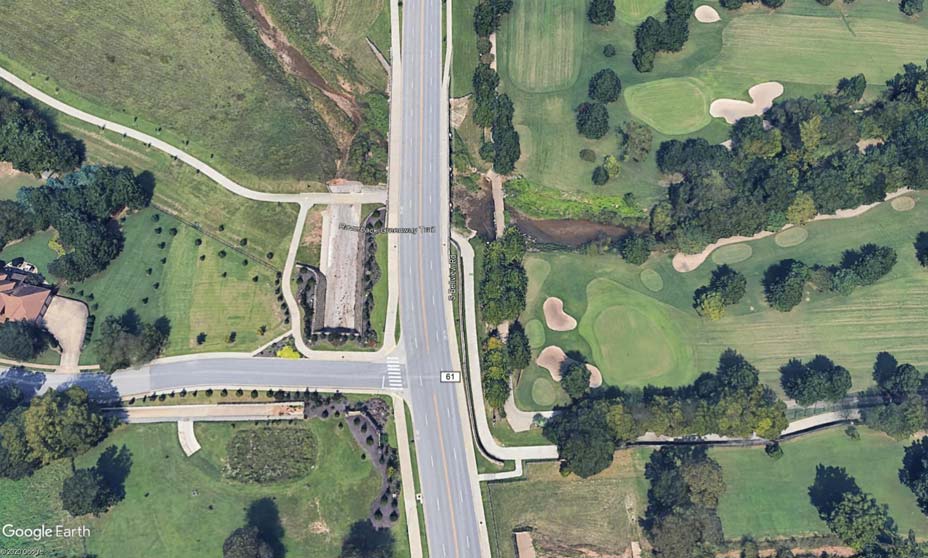

The City of Rogers, Arkansas played a key role in creating the Razorback Greenway, a 37-mile multi-purpose pedestrian and bicycling trail that connects six cities. Originally, the trail used existing infrastructure as much as possible, but as the system grew in popularity, it became a priority to separate pedestrian and cycling traffic from busy roadways and intersections. This was the challenge the City faced in 2017 as it improved the Bellview Road bridge and associated stormwater infrastructure.

THE SOLUTION

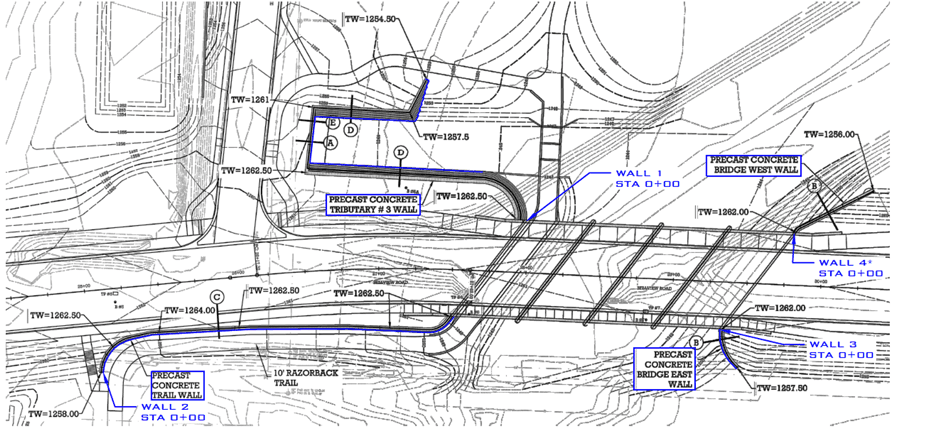

Engineers used Redi-Rock retaining walls at multiple locations for this project, creating a cohesive and efficient solution.

The City had several objectives with this project:

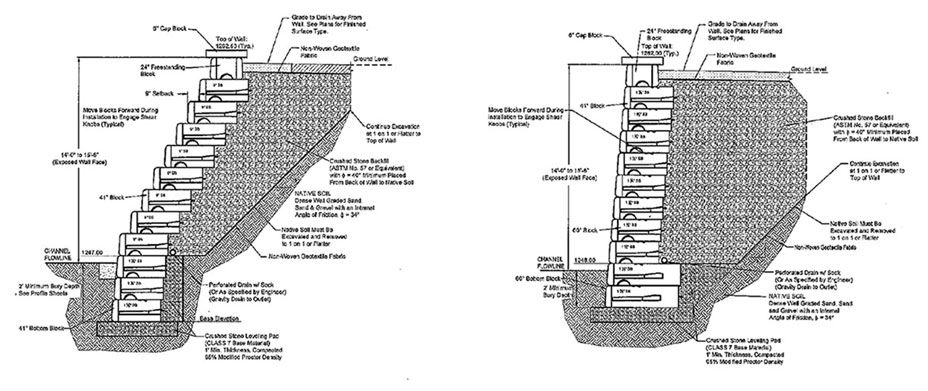

- Diverting the bike path out of traffic and beneath the bridge. To do this, the City needed to enlarge the footprint of the bridge so that the Razorback Greenway Trail could run beneath the bridge, creating a safer passage for pedestrians and cyclists. To save costs, the City wanted to keep the existing roadbed intact. Excavation for geogrid would mean redoing the busy road at significant expense, so project engineer McClelland Engineering proposed using Redi-Rock gravity retaining walls with 9in (230mm) setback blocks to get the job done while leaving the roadbed intact. Engineers from Hood Construction Services completed the wall design on the project, and local Redi-Rock manufacturer Industrial Precast provided the retaining wall blocks for the project.

Cross sections from the engineering plans show the 9in setback blocks (left), as well as the standard 5 degree batter with 60in blocks used at the base of the wall (right), to achieve the necessary heights for the project without using geogrid.

Cross sections from the engineering plans show the 9in setback blocks (left), as well as the standard 5 degree batter with 60in blocks used at the base of the wall (right), to achieve the necessary heights for the project without using geogrid.

- Managing stormwater affecting the area. One portion of the project required bridge wing walls tied to a precast triple box culvert to create a storm water floodway. Engineers on the project again used Redi-Rock 9in (230mm) setback blocks to achieve the height requirements while still eliminating the need for geogrid tiebacks. This portion of the project also included two 90 degree corners which were challenging, but possible due to the flexibility of the Redi-Rock system. Gravity walls like this one are often designed using RRWall+ Software, a powerful geotechnical engineering program used for designing and analyzing Redi-Rock retaining walls.

Redi-Rock 9in setback blocks allowed engineers to achieve the heights necessary for these retaining walls, without requiring geogrid tiebacks.

- Creating space for the path without encroaching on private property. Several portions of the project did not have the space for gravity walls using 9in (230mm) setback blocks because the path abuts private properties, so walls with the standard 5 degree batter blocks were used. This portion of the project used Redi-Rock 60in (1520mm), 41in (1030mm), and 28in (710mm) solid blocks to optimize the wall design and still eliminate the need for geogrid.

In total, the project required 10,700 square feet (994 square meters) of retaining walls, ranging in height from 5 feet (1.5 meters) to 20 feet (6.1 meters) tall.

AESTHETIC UPGRADES

Aesthetics also played a role in choosing Redi-Rock; because this is a highly visible portion of the trail, City officials chose Ledgestone texture, colored to coordinate with the natural stone in the area. The stone texture of the walls also complimented the natural setting of the Greenway while providing the structural integrity needed. Portions of the wall were topped with freestanding blocks and caps to create an aesthetic finish on both sides of the wall.

The Redi-Rock Ledgestone retaining walls allowed the city to create an aesthetic focal point for this highly visible portion of the trail.

INSTALLATION EFFICIENCY

Speed of installation was a key for the City of Rogers. The massive size of Redi-Rock blocks meant more square feet of wall was installed with each block that was placed. Each Redi-Rock block has 5.75 square feet (0.5 square meters) of face and was placed by an excavator and a small crew. Because Redi-Rock blocks are machine set, it saved time for the installers from Second Nature Landscapers while also protecting the crews' backs. A typical installation crew includes 2-3 people and a piece of heavy machinery, and installers typically average upwards of 700 square feet of installation a day once the base course is installed.

BEFORE: In this aerial photo of the Bellview Bridge project, you can see what the area looked like before this project took place.

AFTER: By using Redi-Rock retaining walls for the bridge wing walls, the stormwater floodway, and the triple box culverts, engineers were able to provide a solution for this challenging project.

ECONOMIC IMPACT

Funding for the larger Razorback Greenway project came from a $15 million donation from the Walton Family Foundation, which was matched by the U.S. Department of Transportation. At first, the trail system had plenty of skeptics. "Folks wondered why we would spend a dime on something like this. They assumed the only benefactors would be the extreme cyclists, the spandex crowd," John McLarty, the former assistant director of the Northwest Arkansas Planning Commission and project manager for the Greenway explained to the Walton Family Foundation.

However, the trail's usage has surpassed anyone's estimates and remains busy constantly with pedestrians, casual cyclists, and families - as well as that spandex crowd. As a result of the 37-mile trail's completion, the Walton Family Foundation reported in 2018 that "a cycling subculture has sprung up in the treads of this project. In the breweries, shops and activities geared toward riders, cycling generated $137 million in economic benefits to the region in just the last year."

With this project, the City of Roger made the Razorback Greenway more safe and accessible for pedestrians and cyclists of all abilities. As multi-use trails continue to grow in popularity, local and regional governments are challenged to change their corners of the world in concrete ways. How can Redi-Rock help on your next project?

PROJECT DETAILS

Project: Bellview North Bridge/Razorback Greenway #215 Owner: City of Rogers, Arkansas Civil Engineer: McClelland Consulting Engineers Site Contractor: Crossland Heavy Contractors Retaining Wall Design Engineer: Hood Construction Services Wall Installer: Second Nature Landscapers Manufacturer: Industrial Precast Location: Rogers, Arkansas Year: 2017

PRODUCTS FEATURED IN THIS CASE STUDY

Gravity Retaining Wall Blocks - Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the earth.

Ledgestone Texture Blocks - Redi-Rock Ledgestone blocks mimic the look of real quarried stone.