19.5 Foot (5.9 Meter) Tall Gravity Wall Creates Access For FBI Headquarters

Township chooses Redi-Rock to buffer neighborhood and save existing trees

THE CHALLENGE

In 2011, the Federal Bureau of Investigation (FBI) had plans to relocate its division headquarters from downtown Cincinnati to a high profile mixed-use development site adjacent to Interstate 71 in Sycamore Township, Ohio.

To accommodate the anticipated level of employees and visitors to the new FBI building, the Township constructed a public access drive from Hosbrook Road to the development sites. This new roadway is located between existing residential neighborhoods and a major office building, and the terrain along the new access road included some significant grade challenges.

In order to minimize the earthwork and impacts to the existing wooded buffer between the adjacent residential neighborhoods and the development, a 19.5 foot (5.9 meter) high, 700 foot (213.4 meter) long retaining wall had to be constructed along the south side of the new roadway.

Installing gravity walls allowed the designers to save existing trees that buffer the neighborhood from traffic noise.

THE SOLUTION

After evaluating the costs and impacts of a variety of wall systems including conventional cast in place cantilever walls, drilled soldier pile walls, and conventional segmental walls with geogrid reinforcing, URS contacted local Redi-Rock manufacturer, Redi-Rock Structures of OKI, to explore the potential use of a large block retaining wall system. Following close coordination between URS, Redi-Rock, and the Township, it was determined that the Redi-Rock system would meet the goals of the project better than the other systems.

"Sycamore Township chose Redi-Rock because we had a limited amount of space; we did not want to cut back behind the wall for tie-ins and we didn't want to lose trees that were buffering the neighbors from the project," explained Tracy Kellums, Superintendent for Sycamore Township.

Dave Wormald, P.E. of URS explained further: "One of the primary reasons we chose the Redi-Rock system was because we wanted to design a gravity wall to reduce the amount of excavation required with minimal disruption behind the wall as well as creating an aesthetically pleasing appearance."

Using 9 Inch Setback walls allowed the walls to go taller as gravity structures.

THE DESIGN

It's no secret that Redi-Rock is known for building tall gravity walls using massive, one-ton blocks to get the job done. But this 19.5 foot (5.9 meter) tall wall gave engineers the chance to show just what Redi-Rock blocks are really capable of.

To reach the required 19.5 feet (5.9 meters) with a gravity wall, URS utilized several unique components of the Redi-Rock system to achieve a custom solution for the project without the need for geogrid reinforcement or anchors. URS utilized the Redi-Rock Wall Analysis Software to evaluate a variety of wall cross sections to arrive at the design for the finished wall.

First, URS specified Redi-Rock 60in (1520mm) Solid Base Blocks for the bottom six to eight courses of the wall, with one course of blocks that was buried. The base blocks were topped with several courses of 9in (230mm) setback blocks throughout the wall to vary the batter.

"We incorporated the 9in (230mm) setback blocks to increase the resistance to overturning forces without the need for geogrid reinforcement," Wormald explained.

For the higher courses in the wall where the loading was less, the blocks transitioned to 41in (1030mm) and 28in (710mm) solid blocks to achieve the full height of the wall. The design called for leveling pads and backfilled composed of compacted free-draining aggregate.

The shape of each Redi-Rock block allows concave or convex curve to be built easily. This Ledgestone texture project has aesthetics that the township loves!

Combining a variety of Redi-Rock blocks allowed the wall to achieve its goal height while minimizing excavation and impacts the trees. Plus, the gravity solution saved the Township time and money on installation.

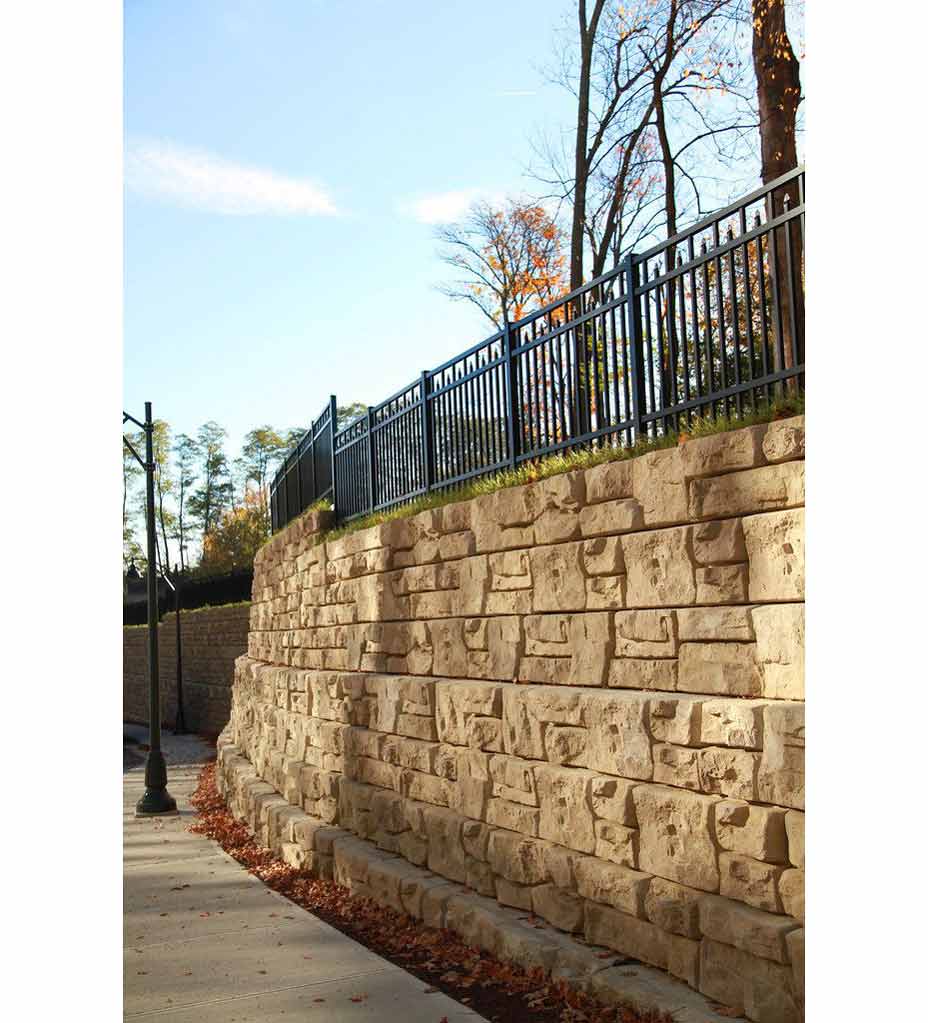

An added benefit on this project was the superior aesthetics the system offered. "We chose the Ledgestone texture because we felt it looked the most like real rock to match up with other retaining walls that we have throughout the Township," Kellums explained.

Ornamental fencing that matched fencing used by the Township for nearby streetscapes was mounted at the top of the wall to reinforce the urban design context of the area.

"Aesthetically, it looks really great," URS noted.

THE OUTCOME

In total, the 8,000 square foot (743 square meter) wall was completed in 25 days, despite several construction delays due to poor weather.

"Now that the wall is finished, we are glad that it is the one we chose," Kellums said. "It is a beautiful structure and we do not feel that we could have found another wall-when you consider size, price, and looks-that could have been better suited for our needs."

PROJECT DETAILS

Project: Ronald Reagan Drive Project #130 Engineer: URS Owner: Sycamore Township, Ohio Installer: Nemann Construction Manufacturer: Redi-Rock Structures of OKI Location: Cincinnati, Ohio Year Built: 2011

PRODUCTS FEATURED IN THIS CASE STUDY

Gravity Retaining Wall Blocks - Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the earth.

Ledgestone Texture Blocks - Redi-Rock Ledgestone blocks give projects a random, stacked stone look.