Rail Yard Renovation Using Redi-Rock

Value engineering leads to savings with PC System walls

THE CHALLENGE

The number one goal of this project was resurrecting a rail yard that hadn't been used in 30 years. LDH Energy is the owner of the tracks, which connect with a CSX line.

The yard includes three rail lines that cross over the top of a concrete box culvert. Old wooden cross tie retaining walls flanking the culvert had deteriorated and needed to be replaced to support the rails. The replacement for these cross tie walls was originally designed as a poured-in-place concrete wall--but value engineering led officials to turn to Redi-Rock based on the fast installation time and overall cost.

Designers chose Redi-Rock PC System retaining walls for this project to support the live loads of the trains passing over this culvert.

THE SOLUTION

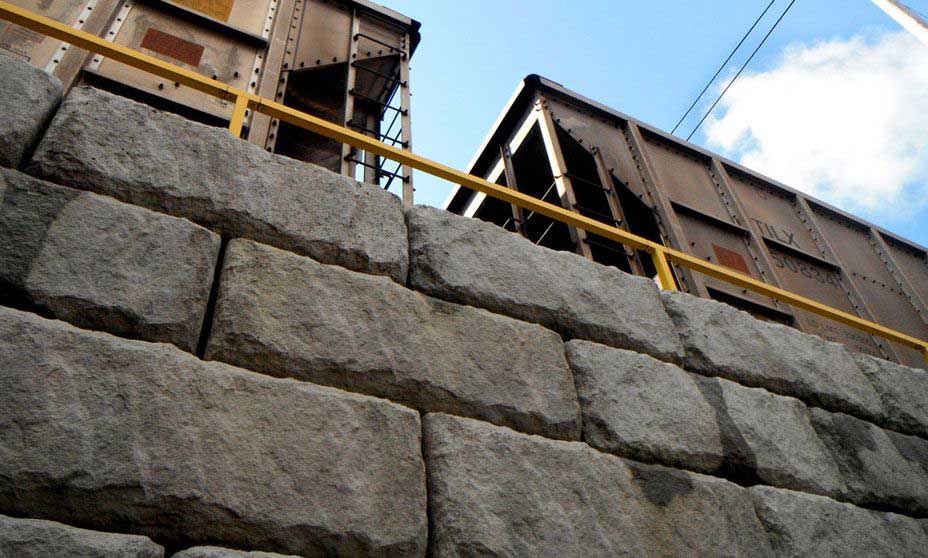

Brad Turman, P.E. and owner of J.B. Turman Engineering, PLLC explained why the Redi-Rock Positive Connection (PC) System for reinforced retaining walls was a great fit for this project: "Three rail lines are located above the 12 foot (3.7 meter) tall walls, and on one side the ties were only 8 feet (2.4 meters) from the face of the wall so there was a large live load right on top of the wall. The forces on the connection on the top of the wall were pretty large, which is why we went with the PC System."

The Redi-Rock PC System combines the massive stability and beautiful cast face textures with the established performance of geogrid reinforcement through a simple and highly efficient positive connection with the Redi-Rock PC Block unit.

The Redi-Rock PC System:

- Delivers an attractive, cost-effective, high-performance retaining wall structure

- Utilizes a corrosion-free reinforcement system without special connection components

- Increases wall height with reduced geosynthetic reinforcement requirements

- Incorporates a massive, ¾ ton, precast concrete block facing unit

- Provides superior seismic performance over other geosynthetic reinforced wall systems

- Offers the incomparable durability of "wet cast", air-entrained concrete

- Simplifies the wall construction sequence resulting in faster installation

- Addresses the long-term connection requirements in the AASHTO LRFD specifications

THE OUTCOME

The project required a total of over 1,800 square feet (167 square meters) of Redi-Rock Limestone texture blocks that were installed over the course of about 4 weeks. "It went up fast for the amount of work they did," explained Pete Byrnes with Atlas Railroad. The Redi-Rock PC System provided a cost-effective, efficient solution to get the rail line back in service as quickly as possible after 30 years of inactivity.

Installation of this Redi-Rock Limestone textured PC retaining wall took just four weeks to complete.

PROJECT DETAILS

Project: LDH Energy Rail Yard Renovation #143 Owner: LDH Energy Installer: JR Contractors Engineer: J.B. Turman Engineering, PLLC; HDR Engineering Location: West Virginia Year Built: 2011

PRODUCTS FEATURED IN THIS CASE STUDY

Reinforced Retaining Wall Blocks - Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks.

Limestone Texture - Redi-Rock Limestone blocks mimic the texture of natural split Limestone.