Redi-Rock Barrier Wall Design Resources

Redi-Rock makes barrier walls simple. With multiple configuration options, dedicated design resources, and expert engineering support, you can confidently design and install barrier walls that meet your project’s needs.

New to Redi-Rock barrier walls?

A barrier retaining wall – also known as a parapet – is a vertical extension added to the top of a retaining wall or bridge. It enhances safety by helping prevent accidents and property damage. In transportation projects, a highway barrier wall serves a similar role, acting as a guardrail to protect vehicles and pedestrians.

Types of Barrier Walls

Details can get technical depending on your site conditions. For the best results, connect with the Redi-Rock engineering support team. We’ll help you navigate your project’s specific requirements.

Barrier Wall using Freestanding Hollow Core (F-HC) and 41 in (1041 mm) Hollow-Core blocks (41-HC)

Barrier Wall using Freestanding Hollow Core (F-HC) tied to positive connection blocks - 28 in (711 mm) PC or 41 in (1041 mm) PC - for enhanced connection and strength

Cast-in-Place walls featuring Redi-Rock blocks and caps as top-of-wall guards and barriers

Can you build a fence on top of a Redi-Rock wall?

Absolutely, but it’s important to note that a fence is considered an accessory, not a barrier wall. Redi-Rock’s Freestanding Hollow-Core blocks are designed to make fence installation easy, and Column blocks can also be used to support fencing where needed. View Accessory solutions.

Barrier Wall Engineering Simplified

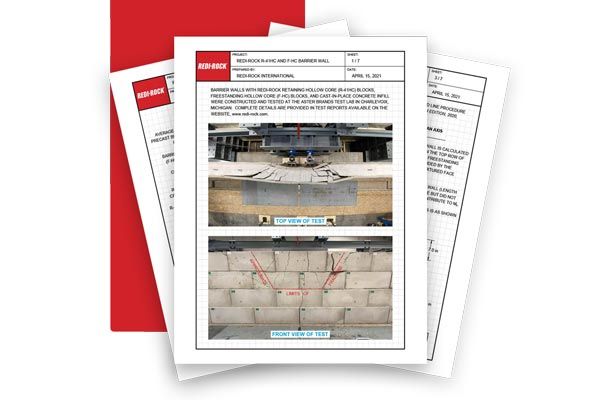

Until now, engineers have been hard pressed to find guidance in parapet barrier wall design. The results of Redi-Rock’s recent barrier testing can now be applied to design projects, ensuring American Association of State Highway and Transportation Officials (AASHTO) and International Building Code (IBC) load requirements are met. Watch the video below outlining our testing process and results.

Barrier Wall Design Resources

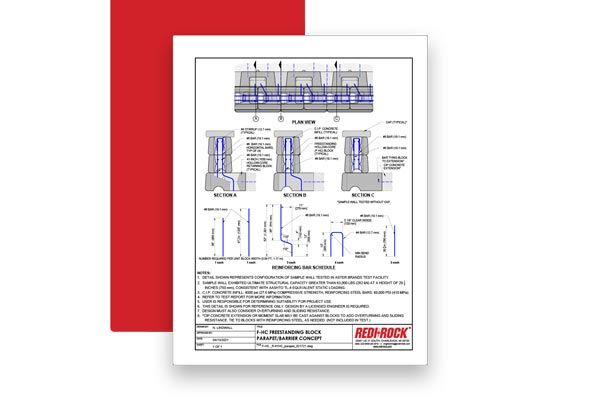

Use the proven resources below to guide your design. Rely on the barrier wall construction detail and sample calculations provided to help you design a parapet barrier wall tailored to your specific application.

Results

Barrier walls constructed according to the Freestanding Hollow-Core Parapet/Barrier Concept detail are capable of resisting an AASHTO TL-4 equivalent static design force of 54.0 kips and exceed the capacity of International Building Code requirements for vehicle barriers.

Important Design Notes:

This testing data reflects the structural capacity of the wall, and barriers would also have to have to be designed to not overturn or slide due to the impact loading.

No vehicle performance impact testing was completed. No attempt was made to consider barrier shape or face texture. This barrier should only be used in low speed applications or in applications where it will not be subject to direct impacts from high-speed traffic.