PRICING

What Does It Cost to Get a Redi-Rock Wall?

Redi-Rock blocks are simple to work with and straightforward to install. However, determining the cost of a custom retaining wall solution takes a little more work. Learn about the factors that influence the pricing of a Redi-Rock retaining wall.

Avg. Read Time: ±6 minutes

The Base Course

Short on time? Here are this page’s key takeaways…

Five factors generally drive the cost of a retaining wall: specific demands of the project site, where the project is located, materials used, engineering and design work, and the actual installation.

Consider consulting a licensed professional engineer when your wall begins to exceed 4 ft (1.2 m) tall.

A well-designed and constructed Redi-Rock wall can have a service life of 75 – 100 years.

Remember to factor in the "lifetime value" of a wall. Inexpensive solutions often fail, leading to considerable repair or replacement costs.

Wall Height

This seems like one of the most obvious variables that will impact your overall project costs. The size and scope of the project will impact the amount of materials you need, as well as the kind of materials. Installation costs will also adjust accordingly to the wall's overall size.

Use our Preliminary Wall Section tool and input four basic features of your project and site to learn more about your potential wall options.

Site-Specific Factors

The specific demands of your site will impact the cost of your wall. The following items can influence the design and installation of your wall, ultimately impacting price:

- permitting agencies

- soil type(s)

- seismic activity

- grade at the top and bottom of wall

- cut wall vs fill wall

- water conditions

- load conditions

Gravity vs. Reinforced

The aspects of your specific site will likely be determining factors in whether you can build a gravity wall or if you will need a reinforced wall – or a hybrid combination of the two! There are advantages and disadvantages of the various wall types that your local contact and your retaining wall engineer will be able to walk you through.

Use Redi-Rock to Overcome Your Site Challenges

Local Redi-Rock Supplier

Each Redi-Rock manufacturer is an independent business – not a franchise – so they set their own pricing to reflect their costs. The cost of manufacturing inputs like cement and aggregate vary greatly by region, so what it costs to produce a block in your neighborhood will be vastly different than a Redi-Rock manufacturer on a different continent.

Geotechnical Conditions

When we talk about geotechnical conditions, it's really just the official way to talk about the type of soil you have. If you live somewhere with shallow bedrock, your wall will be designed differently than somewhere with silty, clay soils.

Seismic Considerations

When the threat of earthquakes are involved, the design parameters for a retaining wall shift to calculate for these natural phenomenon. Someone who lives in a region without any seismic activity might be able to utilize a 12-foot (3.7-meter) gravity wall with standard batter, while your wall factoring in seismic conditions might require geogrid or a larger setback to achieve proper safety factors.

Civil or Site Engineering

Many larger civil projects will require the coordination of a site or civil engineer to keep all of the moving pieces of the project in alignment. Depending on the scale and scope of your wall, this group might sub-contract the work to others or take on the project themselves.

Geotechnical Engineering & Testing

When it comes to retaining walls, accurate information about the types of soils onsite are paramount to a wall that will stand the test of time. Soil samples and other testing may be required to ensure the design suits the conditions onsite.

Wall Design Engineering

It is highly recommended to bring a specialized retaining wall design engineer into the fold of your project to do the actual designing and analyzing of your wall. Their expertise will not only help you meet code requirements and check against all modes of failure, but it can also greatly improve your trust that your wall will stand the test of time.

Your Materials Costs

Oftentimes, people will use the block unit cost to analyze the price of a wall, when in actuality it is just one piece of the puzzle. The cost of materials certainly factor into the lifetime value of a wall; however, as this page outlines, it is not the only variable worth considering.

Blocks and Geogrid

With Redi-Rock, the blocks utilized on a project will vary greatly based upon the geographic and site specific demands. For example, one 9-foot (2.7-meter) tall gravity wall might require two courses of 60in (1720mm) solid blocks used for the base of the wall, while another can meet the site parameters using solely 41in (1030mm) and 28in (710mm) solid blocks. Whether a wall needs geogrid reinforcement will also play into material costs.

Freight and Shipping

One of the reasons that Redi-Rock International works with over 130 manufacturers around the world is that concrete is heavy, and shipping it is expensive. The shorter the distance, the more ideal for the customer. So, depending upon your project location in relation to the manufacturer, this is one of the variables that can differ from wall to wall.

Other Project Materials

When it comes to a retaining wall, it's not just the blocks and grid that create the end result. Your wall design will specify the placement of drain pipes, appropriate backfill materials, geotextile fabrics and more. These materials all contribute to the longevity of a wall, and those costs can vary from project to project.

Your Installation Costs

Just like other aspects of retaining walls, your cost to install Redi-Rock will be dependent on a host of other variables. The good news, though, is installing Redi-Rock is like playing with giant Lego blocks. A small crew with properly-rated machinery can install your wall in a very efficient manner.

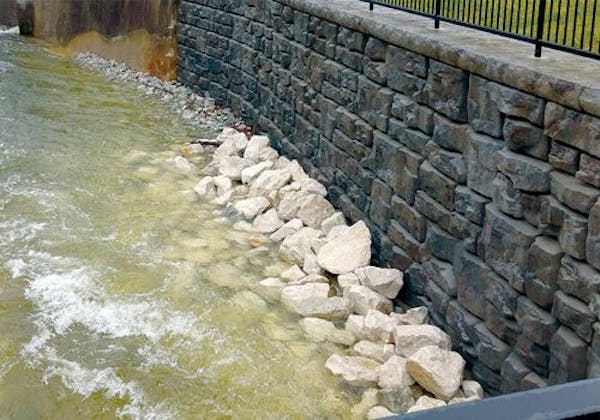

Site Accessibility

The easier it is for the installer's crew to access your site, the more likely the cost of their work will decrease. However, for example, if they need to rent specialized equipment to install the wall from the top because they can't access the bottom of the wall or if they need to dewater a site prior to installation, this extra effort will be reflected in the final price.

Excavation and Site Prep

The type of preparation required before the first blocks can be set will influence your project's timeline and costs. A good contractor will be able to walk you through the steps necessary to not only install your wall, but also explain any hurdles or additional costs you might need to overcome prior to installation. One of the huge benefits of a large block wall system like Redi-Rock is that it minimizes the amount of excavation required in many scenarios.

Labor

Last, but not least, the time it will take for a crew to install your wall will be factored in to the overall cost. Because Redi-Rock is machine set and only requires a small crew, oftentimes it's a faster, more efficient installation process than other types of walls.

Think About the Lifetime Value of Your Wall

A Redi-Rock retaining wall won’t be your least expensive option. But it’s likely to be your most cost-effective choice.

The costs associated with repairing or replacing a failed low-budget retaining wall will likely make you wish you chose differently the first time. In normal conditions, a professionally designed and constructed Redi-Rock wall can provide you with a service life of more than 75 – 100 years or more. There just aren’t many investments anymore that can say the same.

How does Redi-Rock offer the longevity and lifetime value it does?

Redi-Rock blocks are manufactured in highly controlled environments with structural-grade concrete mixes per ASTM C94 or ASTM C685 standards. These standards produce blocks with superior resistance to harsh freeze-thaw cycles, exposure to de-icing chemicals, and both freshwater and saltwater submerged conditions.

Redi-Rock blocks also feature intelligently engineered features that make them simpler to install and able to create gravity, MSE (reinforced), freestanding, or hybrid walls. These blocks don’t just stack, they fit, which typically translates to a more effective installation and a more reliable wall.

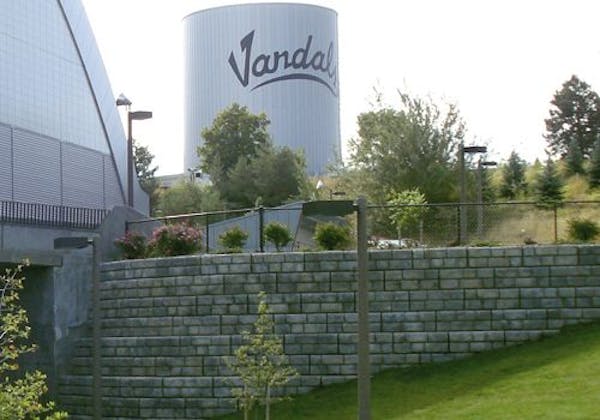

And as the years pass while your Redi-Rock wall stands solid, you won’t have to worry about its appearance, because its quarry-inspired, deeply grooved textures provide a timeless look you’ll never tire of.

So consider the lifetime value of the wall when weighing wall options. Selecting the least expensive option today could quickly become your most expensive option tomorrow.